Category:Nouveaux procédés techniques dans la sidérurgie (1971)

Jump to navigation

Jump to search

Français : Les images de cette catégorie proviennent de la publication de la Communauté européenne du charbon et de l'acier Nouveaux procédés techniques dans la sidérurgie. Les 4 tomes scannés sont disponibles sous licence CC-BY-SA-4.0 sur le site Publications Office of the European Union (OP Portal).

English: The pictures from this category come from the European Coal and Steel Community Nouveaux procédés techniques dans la sidérurgie. The 4 scanned tomes are available under CC-BY-SA-4.0 license on the site Publications Office of the European Union (OP Portal).

Media in category "Nouveaux procédés techniques dans la sidérurgie (1971)"

The following 75 files are in this category, out of 75 total.

-

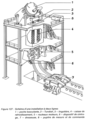

Continuous casting 3D sketch.png 852 × 1,192; 607 KB

-

Continuous casting Casting floor.png 845 × 1,155; 815 KB

-

Continuous casting Dummy bar.png 1,193 × 794; 766 KB

-

Continuous casting mould Copper plates design.png 1,182 × 792; 561 KB

-

Continuous casting mould Machined designs.png 861 × 984; 243 KB

-

Continuous casting mould Seamless pipe design.png 791 × 481; 214 KB

-

Continuous casting slabs.png 1,191 × 799; 768 KB

-

Continuous casting steel yield versus ingot casting.png 1,160 × 694; 525 KB

-

Continuous casting strand Bending on solidified product.png 845 × 1,106; 679 KB

-

Continuous casting strand Curved area.png 844 × 1,142; 787 KB

-

Continuous casting strand Extraction rolls.png 845 × 1,183; 899 KB

-

Continuous casting strand Secondary cooling.png 1,184 × 797; 761 KB

-

Continuous casting strand Straightening.png 1,184 × 784; 747 KB

-

Continuous casting strand Tipper.png 822 × 686; 156 KB

-

Continuous casting strand Torchcutting.png 1,195 × 797; 734 KB

-

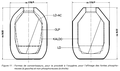

Continuous casting Tundish designs.png 1,186 × 678; 294 KB

-

Continuous casting types with key elements.png 1,183 × 882; 384 KB

-

DH degassing installation Design with balanced vacuum chamber.png 850 × 862; 557 KB

-

DH degassing installation Design with lowerable vacuum chamber.png 818 × 982; 640 KB

-

DH degassing installation Design with raisable ladle.png 833 × 925; 597 KB

-

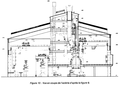

Drawing of a 120t LD steel shop Section view.png 1,165 × 824; 306 KB

-

Drawing of a 120t LD steel shop Top view 01.png 914 × 1,150; 417 KB

-

Flowsheet of solid additions in oxygen steel shop.png 1,169 × 550; 286 KB

-

Internal shapes of oxygen converters.png 1,157 × 685; 218 KB

-

Kaldo converter Charging pig iron cropped.png 759 × 938; 705 KB

-

Kaldo converter Charging pig iron.png 827 × 1,118; 813 KB

-

Kaldo converter drawing.png 833 × 1,022; 407 KB

-

Kaldo converter LD-Kaldo mixed design cropped.png 956 × 664; 529 KB

-

Kaldo converter LD-Kaldo mixed design.png 1,041 × 812; 721 KB

-

Kaldo converter Rotating cropped.png 757 × 657; 386 KB

-

Kaldo converter Rotating.png 824 × 785; 538 KB

-

LD converter bricklaying Bottom lifting car.png 822 × 1,113; 830 KB

-

LD converter bricklaying Bricklaying of bottom.png 1,137 × 769; 775 KB

-

LD converter bricklaying Bricklaying of mouth.png 823 × 813; 529 KB

-

LD converter bricklaying Bricklaying of taping hole.png 1,145 × 777; 734 KB

-

LD converter bricklaying Bricklaying of wall.png 833 × 1,156; 785 KB

-

LD converter bricklaying Drawing.png 826 × 846; 356 KB

-

LD converter bricklaying Pneumatic hammer car.png 1,134 × 766; 823 KB

-

LD converter bricklaying Scafold device picture.png 819 × 1,128; 851 KB

-

LD converter bricklaying Scafold drawing.png 829 × 1,148; 282 KB

-

LD converter bricklaying Scafold lay-out picture.png 1,127 × 827; 719 KB

-

LD converter design Trunnion ring and suspended tilting gear.png 950 × 708; 258 KB

-

LD converter design Trunnion ring and tiliting coupling.png 764 × 1,198; 315 KB

-

LD converter design Trunnion ring and tiliting wheel 1.png 736 × 1,180; 355 KB

-

LD converter design Trunnion ring and tiliting wheel 2.png 756 × 1,205; 312 KB

-

LD converter design Trunnions welded on vessel.png 943 × 763; 606 KB

-

LD converter Gas flow 1.png 816 × 1,157; 345 KB

-

LD converter Gas flow 2.png 820 × 1,201; 238 KB

-

LD converter operation Blowing.png 719 × 995; 716 KB

-

LD converter operation Pig iron taping.png 988 × 765; 576 KB

-

LD converter operation Scrap bucket car 1.png 818 × 1,134; 834 KB

-

LD converter operation Scrap bucket car 2.png 811 × 1,137; 826 KB

-

LD converter operation Scrap loading.png 733 × 1,017; 680 KB

-

LD converter operation Skimming.png 742 × 1,002; 664 KB

-

LD converter operation Steel taping.png 720 × 1,041; 654 KB

-

LD converter operation Tilting for skimming.png 780 × 997; 654 KB

-

LD converter Oxygen lance Cleaning.png 722 × 1,037; 693 KB

-

LD converter Oxygen lance Cross-section view.png 1,372 × 509; 168 KB

-

LD converter Oxygen lance Handling.png 821 × 969; 258 KB

-

LD converter Oxygen lance Lifting device.png 761 × 1,176; 391 KB

-

Oxygen injection in open hearth furnace Burner and lance sketch.png 815 × 511; 198 KB

-

Oxygen injection in open hearth furnace Manual oxygen lance.png 1,152 × 773; 845 KB

-

Oxygen injection in open hearth furnace Roof burner from Shell.png 1,152 × 769; 236 KB

-

Oxygen injection in open hearth furnace Roof lance in operation.png 1,151 × 818; 650 KB

-

Oxygen injection in open hearth furnace Roof lance installation.png 1,067 × 814; 680 KB

-

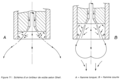

Principle of steel degassing Argon stirring.png 830 × 691; 136 KB

-

Principle of steel degassing Continuous degassing.png 850 × 690; 168 KB

-

Principle of steel degassing Degassing ladle taping.png 848 × 1,201; 215 KB

-

Principle of steel degassing DH process principle.png 1,147 × 841; 99 KB

-

Principle of steel degassing Electromagnetic stirring.png 860 × 656; 158 KB

-

Principle of steel degassing General principle.png 850 × 600; 130 KB

-

Principle of steel degassing Ingot casting in vacuum tank.png 852 × 1,040; 217 KB

-

Principle of steel degassing Ingot casting through sealed mould.png 815 × 957; 194 KB

-

Principle of steel degassing RH process principle.png 966 × 920; 254 KB

-

Research LD converter.png 765 × 1,140; 727 KB